How many people does it take to rebuild a beloved Denver landmark and engineering marvel?

Along with the three principals mentioned on the project vision page, the construction

of the new Electric Fountain required the efforts of many talented people. While not complete,

this list of contributors to the effort is meant to be a small thanks to those who made a personal

commitment to see this project through to a successful completion. Without their help this

project would not have been possible. Entries are listed in the general order they came to

work on the project.

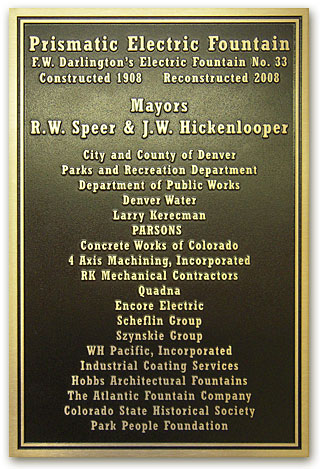

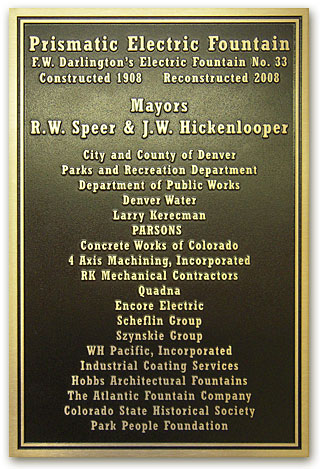

Plaque donated by Parsons, mounted in the fountain vault.

Government Agencies:

Denver Department of Parks and Recreation: Scott Robson, Doug Woods, Helen Kuykendall, Susan Baird,

Juan Marsh, Harry H. Hill, III, Sid Schwarz, Rich Horvat, Teri Henry, JoJo Reynolds, Fred, Bruce,

Hidalgo, Ida, Dan and the rest of the City Park team.

The support from many employees of the DPR was absolutely essential to the success of the project.

Thanks so much to everyone.

Colorado Historical Society: Amy Spong - grant money

Denver Water: Chips Barry, Amy Turney, Jim Weldon, Jon Diebel - technical support and grant money

Denver Department of Public Works: Bill Vidal, Kim Watanabe, Tom Blackman, Raul Rodriguez

The unique partnership between the Department of Public Works and the Department of

Parks and Recreation was the key ingredient to get the construction project completed with a great

team of professionals assembled for the task. The inclusion of the Electric Fountain reconstruction

into the Montclair Storm Drainage Project was the boost that the project needed to become a reality.

Mayor and City Council: John Hickenlooper, Carla Madison

Historic Research:

Colorado Historical Society Library: Rebecca Lintz

The wealth of amazing photographs at the State Historical Society provided much of the

impetus to re-build the Electric Fountain.

Denver Public Library, Western History Collection and PhotosWest:

Without the help of the wonderful staff of the Western History Collection at the Denver Public

Library, an accurate reconstruction of the Electric Fountain would not have been possible.

In particular, Coi Drummond's discovery of an unpublished photograph by Harry Rhodes

helped solve “the mystery of the missing plumbing” for the peacock fan display.

Denver Landmark Preservation Commission: Christie Murata

The Commission achieved a realistic and sensitive balance in their guidance for the

documentation and demolition of the 1908 Electric Fountain and requirements for the

construction of the new Electric Fountain.

Drain-O Rooter:

The dedication of Jimmy Blissett (1966-2008) to clean the deck of the 1908 fountain

vault and patch the old distribution pipes allowed us to see the fountain plumbing and run

the remaining fountain features one last time. This was critical to getting the

reconstruction of the fountain right. Thank you so much Jimmy. We miss you, your friendship,

enthusiasm and eternal optimism very much.

Cultural Resource Historians: Carl McWilliams

Carl produced a beautiful history of Frederic W. Darlington and his “Electric Fountain No. 33” - even

finding the original contract signed by Darlington and Mayor Robert W. Speer in the

Colorado State Archives.

Design and Engineering:

RMH Group: Bob Anderson

Their comprehensive 1999-2000 plans for the restoration of the original Electric Fountain

provided the basis for the creation of the 2007 reconstruction documents.

The Sheflin Group: Ann Sheflin

Ann's work on the engineering and drawings for the new fountain vault gave us the plans

for a structure that will last 75-100 years.

Andrews & Anderson Architects, PC: Nan Anderson

Historic accuracy in the reconstruction of the Electric Fountain was critical and Nan provided

guidance to meet that goal.

ASCG (now WH Pacific, Inc.): Bill Kendall, Mike Galuzzi

While the fountain was not on the initial scope of work for the company charged with the overall design

for the Montclair Basin Storm Drainage Project, they quickly integrated it into the overall

engineering for the project and provided invaluable help in the design and specification

of the new pipelines, infrastructure and equipment for the new fountain.

Hobbs Architectural Fountains: William Hobbs, Wayne Pierce, Colin Goodrich, Thomas Brasher

Thanks to William Hobbs and his team of fountain engineers, we re-designed the layout of the

distribution plumbing, valves and nozzle manifolds to be more efficient and easier to maintain.

Their test tank work with the nozzle angles on the hourglass display was a major help in

getting the new hourglass display to look like the original.

The Szynskie Group (now Scanlon-Szynskie Group), Electrical Engineers:

Charlotte Szynskie provided the leadership necessary for the challenging design/build/document

process for the construction of the fountain power and control systems. Assisted by Chris Ivany and

Arlen Flax, Charlotte provided great personal and moral and chocolate donut support to Larry Kerecman

during the final months of construction of the fountain.

Construction, Fabrication and Software:

Quadna: Dave Neibauer, Brock Tisdale, Travis Ebert, Tim Hill, Mike Niehoff and the

rest of the Quadna team

The A-Team from Quadna repaired the 2001 strainer system, installed improvements on the new

fountain pumps to make them more efficient and installed the sump pumps and submersible

ventilation system in the new fountain vault.

Parsons: Bill Plaehn, Mark Gunderson, Ken Beard, RJ Simmons, Belinda Fitzgerald,

Judy Blakemore, Tamara Cooper

Through the Integrated Construction contract with the Department of Public Works, members of the

Parsons team provided project management, great ideas and personal assistance beyond the call of duty

during the entire construction process.

Concrete Works of Colorado: Mark Lenart, Dick Brasher, Brandon Turner, Brian Jones,

Gary Coffey, Jake Jacobson

The difficult job of building the concrete structure for the new Electric Fountain vault was but

one of many challenges met by the incredible team from Concrete Works. The new intake structure,

pipelines and main water manifold were all part of the CWC contribution to the project. We were very

fortunate to have such an amazing team work on the project, for which they won an award.

Encore Electric: John McGovern, Rob Parkhurst, Dean Schmith, Roger Lopez, Shane Erdman

Under John McGovern's superb leadership, the team from Encore Electric did such a great job on

the electrical work for the Electric Fountain that they won two industry awards. John worked

closely with the electrical engineer to select the long-lasting and reliable electrical products

that will keep the fountain running for decades and was an invaluable partner in the design and

fabrication of the electrical controls for the fountain safety interlock and pump drive systems.

4-Axis Machining: Bob, Robbie and Rene Nickerson and the rest of the team

The incredibly difficult job of creating the manifolds, nozzles and light stands that produce the

wonderful displays of the Electric Fountain was put in the capable hands of 4-Axis Machining and

their precision work has very visible results. With the help of ace welder Dan Frase from

All-Around Fabrication, the metalwork on the fountain deck is a thing of beauty that will

last for generations.

RK Mechanical: Eric Brown and the RK team

The amazing installation of the labyrinth of piping, valves and compressed air system inside the

fountain vault which supplies water to the fountain features was crafted by the team from RK Mechanical.

Atlantic Fountains: Erich Altvater, Bonnie and the rest of the team back in beautiful Clinton, Connecticut

Atlantic Fountains supplied the Oase Nozzle-Star high power LED fountain lighting and a highly customized

version of the ACCESS musical fountain control software which is used to program and schedule the

Electric Fountain shows. Thanks to the longest business meeting in history (LOL) the concepts for

the new generation of controls for the fountain were codified on a rainy night in Clinton.

Erich's years of experience in creating unique and wonderful fountain shows have made the new

Electric Fountain truly special.

These manufacturers and reps of products used on the new Electric Fountain deserve special

thanks for their outstanding customer support during the design and construction of the project:

Hydrel: (Chris Berry, The Lighting Agency) manufacturer of the incandescent underwater

fixtures and electrical junction boxes.

Oase North America: (Aurora Knight) supplier of the Nozzle Star high power LED lighting fixtures.

Pathway Connectivity: David Higgins, president

Manufacturer of the fantastic and ever-reliable eDIN DMX-512 signal processing equipment used to

run the fountain valves and lights.

Colonial Valve: (Dennis DeBlieck, Davis and Davis) supplier of the

pneumatically-operated automation valves.

Cla-Val: (John Tedder, Rocky Mountain Valve) supplier of the pressure relief valve for

the main fountain vault manifold.

Easter-Owens: (Janice Miller, Richard Sturtevant) manufacturer of the custom electrical

control panels.

Current Technology: (Jim Bael, Challenge Technology) Manufacturer of the heavy-duty

electrical surge protection equipment in the fountain vault.